Mozzarella cheese, renowned for its velvety texture and mild flavor, is a culinary treasure that originates in Italy. Whether topping a pizza or pasta dish or accompanying ripe tomatoes with aromatic basil in Caprese salad, there’s little doubt about its importance in Italian cuisine.

The precise combination of ingredients, techniques, and traditions gives mozzarella its unique identity. Making cheese is a skillful craft, a meticulous process that involves curdling milk, forming curds, and stretching them into the iconic mozzarella strands. Stretching and cutting the curds during the cheese-making process led to the name “mozzarella,” a derivation from the Italian verb “mozzare,” which means “to cut off” or “to separate.”

Most of us are familiar with pasteurized mozzarella in grocery stores, a delicate white ball sitting in brine in a sealed plastic container or perhaps one with less moisture content in a vacuum-sealed package. However, authentic artisanal mozzarella cheese that uses raw milk to preserve the full spectrum of flavors and nutrients is meant for enjoying within a few days of its creation.

Like wine, mozzarella is terroir-based, with the raw ingredients determining the quality of the cheese. “The better the animals eat, the better the milk and the mozzarella,” says Master Sommelier Sabata Sagaria in SOMM TV‘s Chef’s Notebook: Mozzarella. In one day, this immersive episode shows the complete circle, from organic farm fields to milk to mozzarella.

Here, we look at the step-by-step process of how Italians make fresh artisanal mozzarella cheese.

Crafting Mozzarella Cheese: Step by Step

At Ammano in Tragliatella, Italy, about 15 miles (25 km) outside of Rome, the process begins with milking the cows at 5 a.m.

“We are organic and grow what the animals eat. So there is a complete circle inside the farm,” says owner and cheesemaker Luigi De Angelis. “We transport the freshest milk from the morning 500 meters from the stable and pump it into a vat to start the cheesemaking process.”

Curdling and Cutting

The cheesemaking begins by heating the milk to kill off bacteria and ready it for fermentation. The addition of a culture or starter kickstarts the fermentation process. “We use fermented whey, a natural starter we make here on the farm,” says De Angelis.

After checking acidity levels, a liquid rennet joins the mix to begin coagulation, making the milk curdle. Once set, the cheesemaking process begins, separating solids (proteins and fats in the milk) and liquid (whey).

De Angelis begins with a first cut, careful not to disturb the natural proteins and fats. “When there is a little bit of whey coming out, that means it’s ready for a second cut,” he says. Following a second delicate cut to ensure the whey is clear, the curds then move through continuous heating and stretching.

Heating and Stretching

After the initial first cuts, the curds release more whey, becoming more pliable. Skilled cheesemakers stretch and fold the curds, developing the characteristic stretchy texture.

“We cut gently, moving all the curd from the bottom (of the vat) to the top,” explains De Angelis. “Having the same size ensures that all the curds have the same amount of moisture.”

When the curd reaches the ideal humidity level, it’s ready for cutting and shaping.

Cutting and Shaping

Like winemaking, cheesemaking is an exact science that is meticulous at every stage for safety and consistency. While testing happens periodically to check acidity levels and monitor temperatures, much of the consistency in texture is achieved through years of practice and feel.

For the consistency to be ready, “it has to run fast (off the spoon) and be nice and shiny,” explains De Angelis. Next, the curds are shredded and mixed with hot water to melt. Once it melts, it is stretched repeatedly until the perfect texture is achieved.

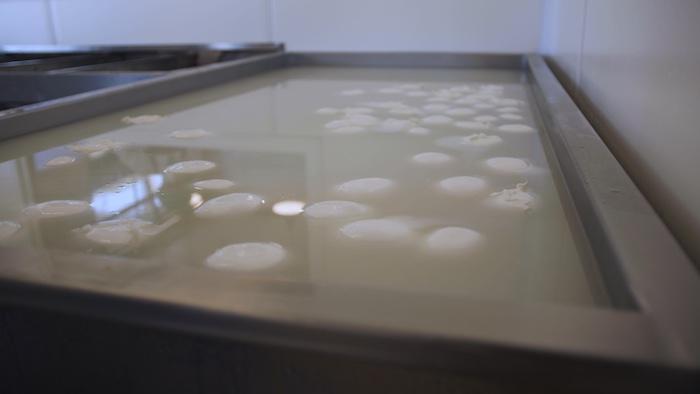

The cheesemaker stretches and shapes the curds into balls before cooling them in a brine solution to enhance flavor, texture, and preservation.

After cooling, the mozzarella is for enjoying fresh or in various dishes.

Enhancing Mozzarella with Wine

When pairing wine with mozzarella, the adage, ‘What grows together, goes together,’ holds true. “I’m looking for something bright and fresh,” says Sabato. “Island-stye or coastal wines that have a bit of brine to them, I think they sing with it.”

In Chef’s Notebook: Mozzarella, Sabato recommends wines from Campania, like Fiano, and also other white Italian grapes like Trebbiano or Frascati. “I think they work nicely with those fresh spring flavors we often associate with mozzarella,” he says.

The world of artisanal mozzarella cheese is a fascinating journey that marries tradition, technique, and taste. As a wine lover, understanding the intricacies of mozzarella cheese-making not only enriches your culinary knowledge but also enhances your ability to create memorable food and wine pairings.